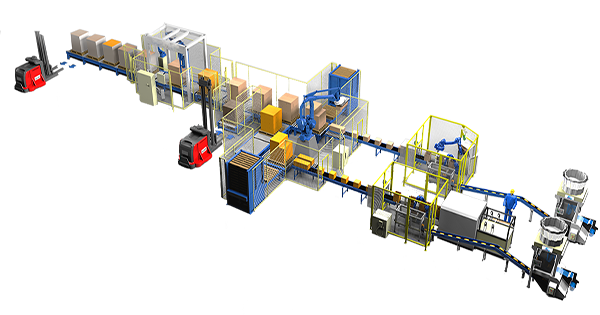

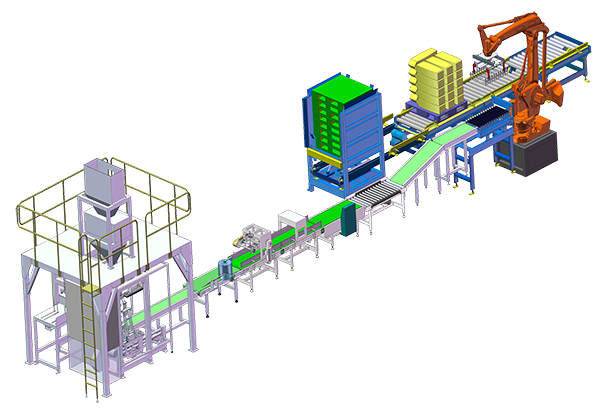

Conveying, Palletizing and Depalletizing System

Conveying and Palletizing System

Palletizers were introduced in the early 1980s and have an end of arm tool (end effector) to grab the product from a conveyor or layer table and position it onto a pallet. Both conventional and robotic palletizers can receive product at a high elevation (typically between 84” - 2.13m to 124” - 3.15m) or low “floor level” elevation (typically at 30” - 0.76m to 36” - 0.91m).

Stretch wrap or stretch film is a highly stretchable that is wrapped around items. The elastic recovery keeps the items tightly bound. In contrast, is applied loosely around an item and shrinks tightly with heat.

It is frequently used to unitize pallet loads but also may be used for bundling smaller items. Types of stretch film include bundling stretch film, hand stretch film, extended core stretch film, machine stretch film and static dissipative film.

Depalletizer

Depalletizer is an automatic machine designed to unload items from a pallet. It serves opposite purpose then Palletizer.

Unloaded item is placed on connected conveyor or into connected machine.

Depalletizer does not require any Machine Operator in order to serve its purpose. However, it does require worker and available forklift to deliver pallet with selected content and to remove emptied pallet.

Tel :

Tel :  Fax : +662 717 1443

Fax : +662 717 1443 line @ :

line @ :