Bulk Bag Discharger, Filler and Conditioner

Detail :

Bulk Bag Discharger

Dust-free loading

A sealed system that prevents the escape of dust throughout the entire discharging process, from untying of bag spouts to retying of partially empty bags to collapsing and retying of empty bags.

- Safety design for operation

- Fast discharging by impacting and pushing device

- Special device control start-stop product discharging

- No product contamination with special closing system

- No product leak and dusty product prevention

- Batching system can be designed

Bulk Bag Filler

- Safety design for operation

- Fully automatic, semi-automatic system are available

- Flexible design for powder and granule application

- Easy to operate

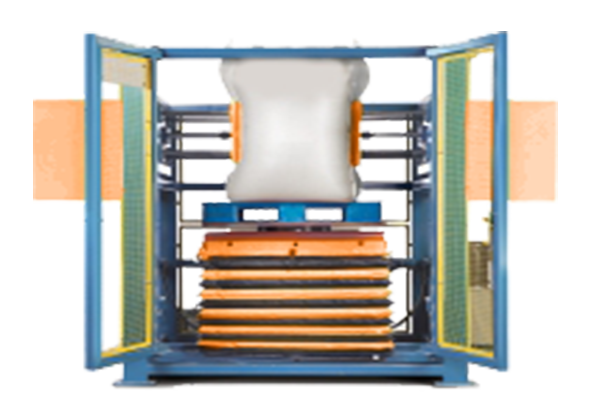

Bulk Bag Conditioners

Loosen bulk solid materials and shipment, enabling bulk bag dischargers to discharge the material through bag spouts. Two hydraulic rams with special plates that press opposing sides of bulk bags to loosen the contents of the bag and accommodate bulk bags of all popular sizes.

Tel :

Tel :  Fax : +662 717 1443

Fax : +662 717 1443 line @ :

line @ :